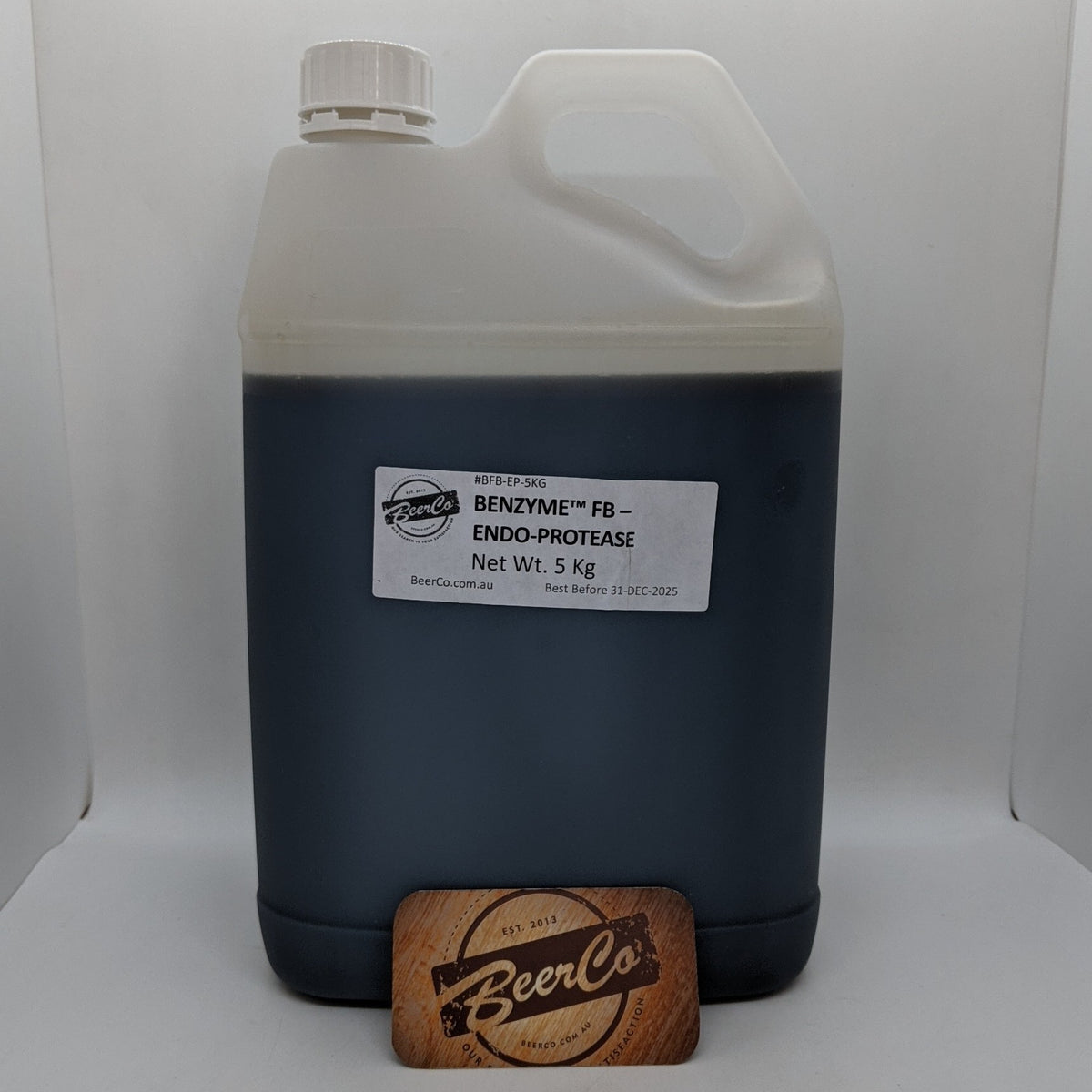

Benzyme FB | endo-protease novozymes

$ 96,95 $ 48,48

Benzyme FB improves yeast health whilst increasing brewhouse efficiency and improving beer flavour stability.

Benzyme FB is an endo-protease that hydrolyzes internal peptide bonds. The result is an increase in FAN levels. This enzyme is suitable if you are using high adjunct ratios with low/no proteolytic activity. Thermo-stable Benzyme FB minimizes LOX (Lipoxygenase) activity during mashing.

In this product the key enzyme activity is provided by serine endoprotease that hydrolyzes internal peptide bonds

Pack Sizes:

- 1Kg HDPE Bottle

- 5Kg HDPE Bottle (SAVE 20% OFF 1Kg Price)

- 25Kg Canister sold as Novozymes FAN Boost™ | endo-protease

PRODUCT CHARACTERISTICS/PROPERTIES

Component name: Protease (Subtilisin)

Activity: 4 AU-A/g

Color: Brown

Physical form: Liquid

Approximate density (g/ml) 1.17

Color can vary from batch to batch. Color intensity is not an indication of enzyme activity.

Novozymes – Brewing Application sheet – Fermentation control and FAN optimization – Neutrase® 0.8 L BrewQ, FAN Boost™

Key Benefits:

FAN Generation

This product hydrolyzes internal peptide bonds. This reaction supports the peptidases naturally present in cereals. That generates more FAN to increase levels in the wort.

Increased brewhouse capacity

The way this product modifies the protein matrix allows for shorter mashing times. It can also have a positive impact on wort filtration and extract yields in the brewhouse. That boosts your brewhouse capacity.

Ensure consistent fermentations

Yeast is a living organism and needs proteins to grow and multiply. This product boosts FAN levels to make more nitrogen compounds available for yeast to metabolize during fermentation. That improves the health of your yeast and ensures consistent fermentation performance.

Manage flavor control

FAN levels in the wort influence the formation of flavor compounds. These in turn impact the flavor of the resulting beer. If FAN levels are too high or too low, it can lead to off-flavors in your final beers. By helping you manage FAN levels, this product helps you avoid off-flavors in your final beer.

Improve physical stability

Physical stability is a key factor in beer quality. Proteins are a common cause of haze especially with high-barley-inclusion recipes. By degrading proteins, this product may improve the clarity of your beers.

Usage – Benzyme FB | endo-protease

Lipoxygenase (LOX) activity is derived from malted barley and is implicated in the lipid oxidation and stale flavor formation during malting and mashing, that can later surface as defects in finished beer. LOX activity during mashing can be reduced or avoided by eliminating the standard protein rest at 45–50°C and conducting proteolysis at higher temperatures. LOX rapidly denatures at temperatures above 65°C.

Therefore, to ensure sufficient FAN and minimize LOX activity during mashing, a thermostable protease is advantageous. BeerCo offers Benzyme FB for FAN generation at higher temperatures, ensuring high-quality FAN production and flavor stable beer.

● FAN control for improved yeast growth and stable fermentations

● Eliminate the need for standard protein rest to generate FAN, saving the brew house time and energy

● Enable high adjunct inclusion rates

● Enhanced flavor stability by avoiding Lipoxygenase (LOX) working temperature

Benzyme FB is added at mash-in, once grist and liquor are added (do not add directly to heated liquor). The product is completely deactivated during wort boiling. The proper dosage of Benzyme FB will depend on malt quality, adjunct ratio and FAN specification. A standard liquefaction and mashing profile is illustrated in figure 1, while a recommended liquefaction and mashing profile when using Benzyme FB is illustrated in figure 2.

With the addition of Benzyme FB in the cereal cooker the standard protein rest in the main mash can be eliminated as shown in figure 3.

This allows for energy savings and reduction in main-mash vessel occupancy time. Also, the liquefaction and mashing profile gives the option to use the standard cereal cooker and mash tun setup, or a single vessel.

Dosage

Considering a recipe of 55:45 corn grits to barley malt, a dosage of 2.5 kg Benzyme FB per ton grist was found to be effective at producing 12 mg/L/°P of FAN in the wort. The FAN dosage recommendation for malt-wort is 10–18 mg/L/°P.

Optimum temperature:

- 65-75°C

Optimum pH and temperature:

Benzyme FB | The working conditions for Benzyme FB is at normal brewing pH and a temperature of 65–75°C

Product Data:

| Declared enzyme | Protease (Subtilisin) |

| Catalyzes the following reaction: | Serine endoprotease that hydrolyzes internal peptide bonds |

| Declared activity | 4 AU_A/g |

| E.C./I.U.B no.: | 3.4.21.62 |

| Physical form | Liquid |

| Production method | The enzyme is manufactured via fermentation of a microorganism not present in the final product. The production organism is not modified using modern biotechnology |

| Density | 1.17 g/ml |

More information can be found in the “Brewing Handbook”.

Stability

Please see the Novozymes | FAN Boost™ | Product Data Sheet

Safety, handling and storage

Safety, handling and storage guidelines are provided with all products.

| Size | 1 Kg, 5 Kg |

|---|

Fast shipping and professional packing

We offer a wide range of shipping options due to our long-running partnerships with UPS, FedEx and DHL. Our warehouse staff are highly trained and will package your items according to our precise and precise specifications. Before shipping, all goods are thoroughly inspected and securely secured. Every day we ship hundreds of packages to our customers from all over the world. This is a sign of our commitment to be the largest online retailer worldwide. The warehouses are located situated in Europe as much as they are in USA.

Note: Orders containing multiple items will have a different processing period for each item.

Before shipping the items, our staff will carry out an extensive inspection of the products you have ordered. The majority of orders are delivered within 48 hrs. The delivery time should be between 3-7 working days.

Returns

We don't manage the stock in our factory and warehouse. Actual stock levels may fluctuate at any moment. Be aware that it's possible that your order will be out of stock after you have placed the order.

Our policy is for 30 days. Unfortunately, if 30 days have passed from the date you purchased the product, we are unable to offer you a return or exchange.

The item must not be used, and it must be in the original packaging. It must also be in the original packaging.

Related products

Brewing Aids

Equipment

Brewing Aids

Equipment

Equipment

Equipment

Equipment

Equipment