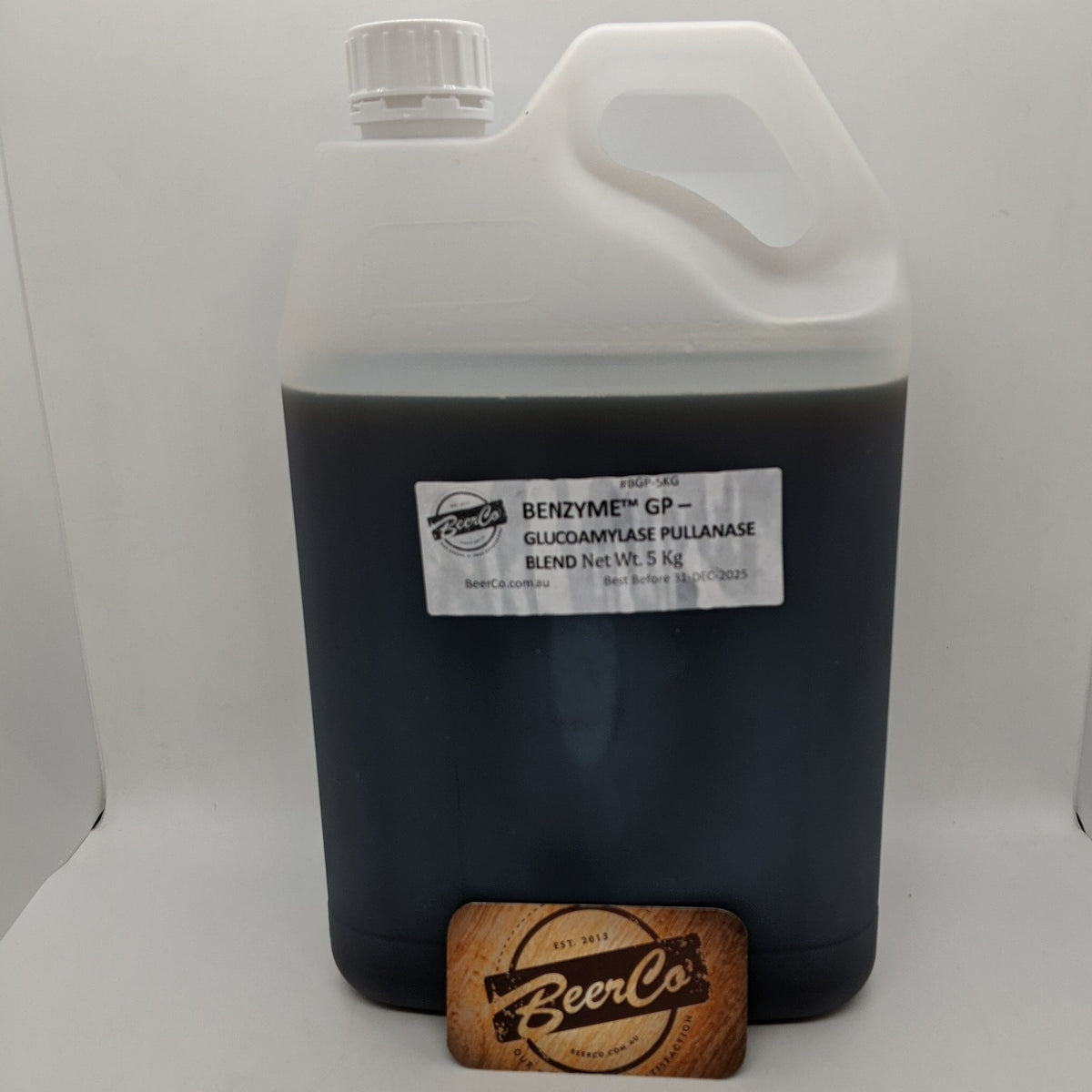

Benzyme GP | Glucoamylase Pullanase Enzymes Blend novozymes

$ 77,95 $ 38,98

Benzyme GP is a cost-effective solution for highly attenuated beers. It allows you to achieve a very high real degree of fermentation (RDF).

Benzyme GP is a high-performing blend of glucoamylase and pullulanase. With Benzyme GP, you can hit high attenuation targets in short reaction times.

Pack Sizes:

- 1 Kg HDPE Bottle

- 5 Kg HDPE Bottle (SAVE 20% OFF 1 Kg Price)

- 25 Kg Canister Novozymes | Attenuzyme® Pro

Key Benefits:

- Achieve desired attenuation

This product delivers predictable and targeted real degree of fermentation (RDF). It helps you to control the percentage of fermentable sugars you derive from starch. It allows you to increase fermentable sugars or maintain them at a specific level so you can achieve your desired attenuation.

- Accelerate fermentation

By releasing more fermentable sugars in the brewhouse, this product supports the need to accelerate your fermentation times.

- For ultra-light beers

With the synergistic activity in this enzyme blend you can hit high attenuation targets in short reaction times. That allows you to produce ultra-light beers.

- Increase brewhouse capacity

This fast-acting product shortens mashing times. That allows you to increase brewhouse capacity while saving time and energy.

PRODUCT CHARACTERISTICS/PROPERTIES

Component name: Blend of Glucoamylase and Pullulanase

Activity:

Side activities:

Color:

Physical form: Liquid

- Benzyme GP – Product Data Sheet

- Benzyme GP – Safety Data Sheet

- Benzyme GP – Application Sheet – Attenuation Control and Light Beer Production

How glucoamylase-pullulanase enzyme blends help control attenuation in brewing

Glucoamylases break down the α-1,4-glucosidic bonds in amylase and amylopectin. Pullulanases break down α-1,6-glucosidic bonds in amylopectin. These two enzymes work synergistically to quickly hydrolyze amylopectin and amylose. That allows brewers to achieve the high attenuation targets and short reaction times ultra-light beers need.

Glucoamylases hydrolyze starch. They break α-1,4-glucosidic linkages at the non-reducing ends of amylase and amylopectin. Pullulanases also hydrolyze starch, but they’re de-branching enzymes. They break down α-1,6-glucosidic bonds in amylopectin.

Glucoamylases are typically brewers’ first choice when producing highly attenuated beers. Consumers know these as light or low-calorie beers.

Combined with pullulanases, glucoamylases speed up starch breakdown even more. That’s why brewers use this synergistic enzyme blend in ultra-light beer production. It allows them to reach attenuation targets in even shorter conversion times.

pH and temperature curves

Attenuation enzymes can be used in the brewhouse or possibly during fermentation.

The degree of attenuation desired is governed by the choice of attenuation enzyme (glucoamylase, α-amylase, pullulanase or combination), enzyme stability (temperature and pH), enzyme dosage, conversion temperature and conversion time.

When choosing an enzyme solution for attenuation control, it is important to look at the activity curves for each based on temperature and pH. Select an enzyme solution that has significant activity and stability where you want to use it – in either mashing or fermentation.

Fig. 6.4-1 illustrates the temperature and pH activity curves for Novozymes’ attenuation enzymes. It is clear that from a pH point of view, all enzymes have significant activity in the typical pH ranges encountered during brewing. From a temperature perspective, Attenuzyme Core (and Attenuzyme Pro) and AMG 300L BrewQ have high activity between 60°C and 70°C and would be more suitable for mashing application than Fungamyl BrewQ, which undergoes significant denaturation in this temperature range. Therefore, Fungamyl BrewQ may be of more use in fermentation applications.

Usage

More information can be found in the “Brewing Handbook”.

Stability

Please see the Benzyme GP – Product Data Sheet

Safety, handling and storage

Recommended storage: 0-10 °C (32-50 °F) Packaging must be kept intact, dry, and away from sunlight. Please follow the recommendations and use the product before the best-before date to avoid the need for a higher dosage.

Best before: You will find the best-before date in the certificate of analysis or on the product label. The product gives optimal performance when stored as recommended

and used prior to the best-before date.

| Size | 1 Kg, 5 Kg |

|---|

Fast shipping and professional packing

We offer a wide range of shipping options due to our long-running partnerships with UPS, FedEx and DHL. Our warehouse staff are highly trained and will package your items according to our precise and precise specifications. Before shipping, all goods are thoroughly inspected and securely secured. Every day we ship hundreds of packages to our customers from all over the world. This is a sign of our commitment to be the largest online retailer worldwide. The warehouses are located situated in Europe as much as they are in USA.

Note: Orders containing multiple items will have a different processing period for each item.

Before shipping the items, our staff will carry out an extensive inspection of the products you have ordered. The majority of orders are delivered within 48 hrs. The delivery time should be between 3-7 working days.

Returns

We don't manage the stock in our factory and warehouse. Actual stock levels may fluctuate at any moment. Be aware that it's possible that your order will be out of stock after you have placed the order.

Our policy is for 30 days. Unfortunately, if 30 days have passed from the date you purchased the product, we are unable to offer you a return or exchange.

The item must not be used, and it must be in the original packaging. It must also be in the original packaging.

Related products

Equipment

Equipment

Brewing Aids

Equipment

Brewing Aids

Equipment

Equipment

Equipment

Brewing Aids