Citric Acid is an organic acid found in beer normally within the range of 50 to 250 parts per million. It is produced as a result of yeast metabolism and is a key component of the tricarboxylic acid cycle, which is also referred to as the Krebs or citric acid cycle. Although it contributes to the overall acidity of the beer, citric acid has little impact on the overall flavour. It is sometimes added to increase the acidity of some low-alcohol and non-alcoholic beers where incomplete fermentation fails to increase acidity to an appropriate level.

Craft brewers and homebrewers have occasionally used additions of citric acid to lend some tartness to Belgian-style witbier; although some tartness is traditional, it has historically been the result of lactic bacterial activity.

Pack Sizes:

- 450g Plastic Tub

- 1 Kg Bag (SAVE 37% OFF 450g Price)

- 5 Kg Bag (SAVE 25% OFF 1Kg Price

- 25 Kg Bag (SAVE 15% OFF 5Kg Price)

Citric Acid use in Cleaning and Sanitation:

Citric acid has also been used as a cleaning agent, particularly in the removal of “beer-stone” from fermentation vessels.

Used primarily in sanitizing solutions to lower pH, therefore making the SO2 solution more effective. Use 1 tbsp per gallon along with 1 tbsp meta per gallon. Citric is not added directly to must prior to either primary or ml fermentation as its metabolism can lead to volatile acidity.

A rough approximate of weight is 1 tsp = 4 grams. We highly recommend using a scale to weigh the product for an accurate dose. We do not recommend relying on these rough conversions for accurate dosage rates.

Citric Acid use in Winemaking

Citric acid is used in wine making as a flavour enhancer and, if required, to reduce the pH of the must to the correct range of approximately 3.2 – 3.5.

USAGE

If pH is 3.6 add 1g/litre

If pH is 3.8 add 2g/litre.

If pH is 4.0 add 3g/litre.

NOTE: More than 3g/litre is not recommended.

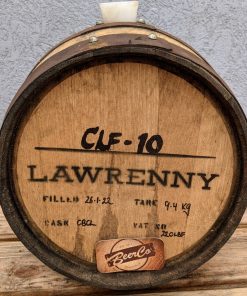

Citric Acid Use in Barrel Storage

An effective alternative is to fill and store barrels with a sulfur-citric holding solution. This holding solution will promote sterility, keep the barrels swelled and smelling sweet. It is not recommended for new barrels or barrels less than one year old as precious oak extract would be stripped.

The holding solution is prepared using 1 tsp of citric acid and 1.5 tsp of potassium metabisulfite for each gallon (4 L) of barrel volume. For example, for a 15-gallon (57 L) barrel, use 15 tsp of citric acid and 23 tsp of potassium metabisulfite. (Note: 3 tsp = 1 tbsp) Dissolve these in one gallon of hot water. Fill the barrel two-thirds with water, add the holding solution, top up the barrel with cool water, and bung the barrel. Top up the barrel with a holding solution once a month to replace solution lost by evaporation and absorption into the wood. The barrel can be stored indefinitely without the risk of spoilage. During storage, rotate the barrel 45° in either direction every time you top up to keep the bung area soaked. This will prevent the bung area from drying out and protect it from spoilage organism growth. Caution: The sulfur-citric holding solution will etch a concrete floor. Rinse the floor with water to prevent this.

Citric Acid Use in Brewed Beverages like Hard Seltzers

Citric acid is found in most fruits and adds the sour flavor consumers know and love. Hard seltzers with a pH of 3.25 are similar to popular sodas and drinks, such as Mountain Dew and Sprite, making them recognizable and more enjoyable. Lowering the pH of water (7) to the acidic range requires citric acid, which also produces the “true-to-fruit” and juicy character of beverages.