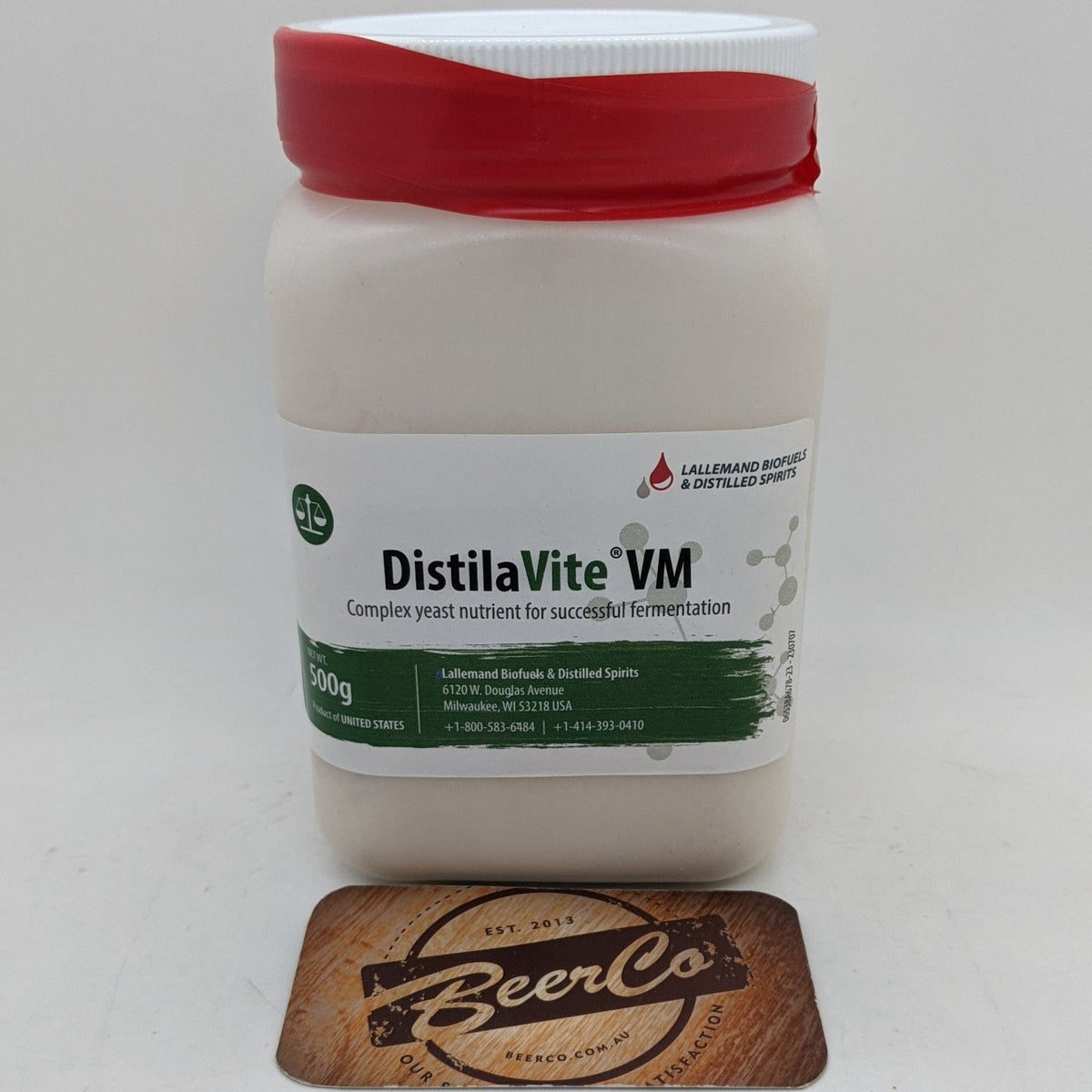

DistilaVite® VM | Lallemand Craft Distilling Yeast Nutrient IMCD

$ 93,95 $ 46,98

DistilaVite® VM Nutrient for use in beverage fermentations

DistilaVite® VM yeast nutrient is intended for use in beverage alcohol fermentations. It contains a proprietary blend of enzymes, inorganic nitrogen, organic nitrogen and trace minerals to provide yeast balanced nutrients for growth and reproduction.

Applications:

- DistilaVite® VM can be used not only during the rehydration step on starch-based feedstocks but also during fermentation.

Dosage:

- Use 1-2 lbs per 100 barrels [454 – 908g per 11,924 litres / 12hL]

- Distilling (Molasses): 2-4 ounces per 1,000 gallons [57-114g per 3,785 Litres / 38hL]

- Distilling (Grain): 2-4 ounces per 1,000 gallons [57-114g per 3,785 Litres / 38hL]

DistilaVite®

How to get a successful fermentation

During the process of alcoholic fermentation yeast, which is a complex living organism, is subject to various stressors: temperature, ethanol, pH, organic acids and others. In order to get a successful fermentation, yeast needs a balanced nutrient package which will maximize its potential to deliver high alcohol yields and a consistent congener profile.

The first nutrient yeast needs is nitrogen. Nitrogen is naturally present in all the feedstocks we use to produce spirits however, often the natural content is not sufficient or the yeast cannot uptake efficiently or at all . Yeast can uptake ammonium ions, small peptides and α-amino acids except proline . These three sources of nitrogen are collectively referred to as the YAN: Yeast Assimilable Nitrogen. The Free Amino Nitrogen (FAN) only includes α-amino acids and small peptides.

Our studies and other publications on this topic illustrate that a deficiency of nitrogen impacts the yeast growth and can cause slow and sluggish fermentation. In order to manage fermentation properly, it is recommended to use nitrogen in an inorganic (ammonium salts and not urea) or in an organic form. Organic nitrogen has been shown to be effective not only for ensuring efficient fermentation but also to develop and enhance the aromatic potential of the feedstock.

However, yeast is complex and needs other key nutrients such as minerals and vitamins which are necessary to support the enzymes involved in the biochemical reactions of the glycolysis and the fermentation.

To ensure that these other key minerals and vitamins are present we recommend to add complex nutrients. They can be added during the rehydration step using a dedicated nutrient and/or they can be added during the fermentation.

The last issue we have to consider is the feedstock used for the production of distilled spirits. There are two types of feedstocks that have to be managed differently: the first is sugar-based feedstocks (molasses, cane-juice, fruit, etc) and secondly starch-based feedstocks (corn, rye, wheat, barley, etc).

Considering all the different aspects of yeast nutritional requirements during the fermentation, Lallemand Craft Distilling has developed a range of nutrients tailored to the various applications.

- DistilaVite® VM – Lallemand Craft Distilling – Technical Data Sheet

- DistilaVite® VM – Lallemand Craft Distilling – Safety Data Sheet

Fast shipping and professional packing

We offer a wide range of shipping options due to our long-running partnerships with UPS, FedEx and DHL. Our warehouse staff are highly trained and will package your items according to our precise and precise specifications. Before shipping, all goods are thoroughly inspected and securely secured. Every day we ship hundreds of packages to our customers from all over the world. This is a sign of our commitment to be the largest online retailer worldwide. The warehouses are located situated in Europe as much as they are in USA.

Note: Orders containing multiple items will have a different processing period for each item.

Before shipping the items, our staff will carry out an extensive inspection of the products you have ordered. The majority of orders are delivered within 48 hrs. The delivery time should be between 3-7 working days.

Returns

We don't manage the stock in our factory and warehouse. Actual stock levels may fluctuate at any moment. Be aware that it's possible that your order will be out of stock after you have placed the order.

Our policy is for 30 days. Unfortunately, if 30 days have passed from the date you purchased the product, we are unable to offer you a return or exchange.

The item must not be used, and it must be in the original packaging. It must also be in the original packaging.

Related products

Equipment

Brewing Aids

Brewing Aids

Brewing Aids

Brewing Aids

Brewing Aids

Equipment

Brewing Aids

Equipment

Brewing Aids