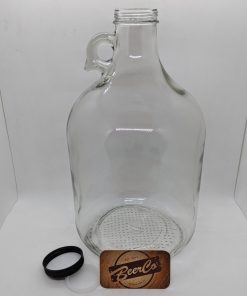

einkorn | Wheat Vodka All Grain Recipe Kit BeerCo

$ 54,95 $ 27,48

The cultivation of wheat was started some 10,000 years ago, with its origin being traced back to south east Turkey. It was called Einkorn. Wheat is synonymous with pure high quality Vodka spirits. Vodka is a pure spirit and can be made with a multiple of raw materials from wheat to barley, corn, and even potatoes and fruit and sugar. Here we pay homage to einkorn and give you a simple All Grain Distillers Recipe Kit to make your einkorn | Wheat Vodka wash. Where you take it from there and how you distil it to make your own perfect Vodka is up to you.

ваше здоровье Cheers #enjoyresponsibly #distilsafely

VITAL STATS:

Mash Tun Batch Size: 41 Litres / 10.8 US Gallons

Fermentation Batch Sizes: 25 Litres / 6.6 US Gallons

Boil Time: 0 mins

PROPERTIES

est. OG 1.094

est. FG 1.022

est. Wash ABV 9.5%

Malt and Unmalted Cereals:

Weight |

% |

Name |

| 6.70 Kg | 67% | UniGrain Rolled Red Wheat |

| 3.30 Kg | 33% | Crisp Wheat Malt |

| 10.00 Kg | 100% |

Yeast:

- Still Spirits Distiller’s Vodka Yeast 20g Sachet

Aids:

Water Adjustments (Optional to lower mash pH to 5.8 to 6.0 pre-grain additions):

- 3 tsp (15g) of Calcium Sulphate – Gypsum (sold separately)

- 3 tsp (15g) of Citric Acid (sold separately)

enzymes:

- Still Spirits – Distiller’s Glucoamylase Enzyme – 12g

Method:

Thoroughly mix the 15g (3-tsp) of gypsum into the 34 Litres of strike water, and measure the pH using the pH meter or the range 2-12 pH papers. Use this pH measurement to determine what pH adjustment the water requires.

Lets assume the pH, as with most municipal tap waters, is approximately 8 or 9. Citric acid powder additions should be 1¼ ml (¼ tsp), and will take about 15g (3 tsp) or so in total to achieve pH 5.8 to 6.0 from a source water of pH 8.5.

Heat the pH treated water (34L) to a strike temperature of 74C (165F) and Mash In the Rolled Wheat for an initial first step mash at about 68C (155F) or higher. Stir the mash for about five minutes while the starches disperse (i.e. gel into a thick porridge). It should take about 15 to 25 minutes for the temperature to cool to 66.5C (152F). The mash should be stirred every five minutes or so until it cools to that temperature.

When the mash is at 66.5C (152F) stir in the 3.3Kg of crushed wheat malt. The mash temperature should rest at 65C (149 F).

Cover the mash tun and leave it for 90 minutes for the starches to fully convert to sugars. Its helpful to stir the mash every 15 minutes or so during the 90-minute conversion rest.

Optional – draw a sample and do a mash iodine conversion test before chilling to fermentation temperature.

Cool the mash down to below 65C (149F) and add 1 x 12g Sachet of Distiller’s Glucoamylase Enzyme, stir well cover and hold at 50-60C (122-140F) and allow to stand for 1 hour before cooling for fermentation. Alternatively if you plan to ferment on the grain, add to the mash/wort mixture along with yeast and ferment at optimum 30-35C (86-95F) ambient air temperature for simultaneous saccrification and fermentation.

Using an immersion or counterflow chiller cool the mash to fermentation temperature after the 90-minute conversion rest is complete. Alternatively, the mash can even be left for eight or ten hours (e.g. overnight) to cool to fermentation temperature (20-32C).

Pitch the Still Spirits Distiller’s Vodka Yeast 20g Sachet once called to below 32C and ferment between 20-32C. A cooler fermentation will produce less esters and take longer to ferment for an arguably cleaner more pure flavour. A warmer fermentation will ferment more quickly and produce some more ester character to your wash and final spirit. Note: if you are fermenting on grain and using your 12g Sachet of Distiller’s Glucoamylase Enzyme during fermentation and not during the mash you will need to ferment between 30-32C.

Add Still Spirits – Turbo Carbon 130g immediately after pitching the Yeast for removing impurities during fermentation and for ultimate distillate quality.

If fermenting on the grain, remove grain by straining through a BIAB or similar into a secondary fermenter.

Once fermentation is complete and the grain removed (if fermenting on the grain). Stir the wash vigorously to remove all of the remaining CO2. Once degassed, add the contents of Part A of Still Spirits – Turbo Clear 130g stir well, then leave for 1 hour to stand.

After 1 hour, slowly pour Part B of Still Spirits – Turbo Clear 130g evenly over the top of the wash while stirring gently to help spread it evenly. Do not stir vigorously as this will disrupt the clearing process. Leave to clear for 24 hours. During this time Part B will drop down from the top, taking all unwanted yeast and sediment with it to the bottom.

Move the wash to your Still and prepare to Distil Happy!

einkorn | Wheat Vodka All Grain Recipe Kit Contents:

- 6.70 Kg UniGrain Rolled Red Wheat (unmilled)

- 3.30 Kg Crisp Wheat Malt (milled or unmilled)

- Still Spirits Distiller’s Vodka Yeast 20g Sachet

- Still Spirits – Distiller’s Glucoamylase Enzyme – 12g

- Still Spirits – Turbo Carbon 130g

- Still Spirits – Turbo Clear 130g

| Title | Milled, Unmilled |

|---|

Fast shipping and professional packing

We offer a wide range of shipping options due to our long-running partnerships with UPS, FedEx and DHL. Our warehouse staff are highly trained and will package your items according to our precise and precise specifications. Before shipping, all goods are thoroughly inspected and securely secured. Every day we ship hundreds of packages to our customers from all over the world. This is a sign of our commitment to be the largest online retailer worldwide. The warehouses are located situated in Europe as much as they are in USA.

Note: Orders containing multiple items will have a different processing period for each item.

Before shipping the items, our staff will carry out an extensive inspection of the products you have ordered. The majority of orders are delivered within 48 hrs. The delivery time should be between 3-7 working days.

Returns

We don't manage the stock in our factory and warehouse. Actual stock levels may fluctuate at any moment. Be aware that it's possible that your order will be out of stock after you have placed the order.

Our policy is for 30 days. Unfortunately, if 30 days have passed from the date you purchased the product, we are unable to offer you a return or exchange.

The item must not be used, and it must be in the original packaging. It must also be in the original packaging.

Related products

Equipment

Equipment

Equipment

Brewing Aids

Equipment

Brewing Aids

Equipment

Brewing Aids

Brewing Aids

Equipment

Brewing Aids